Introduction to Geogrid Reinforcement

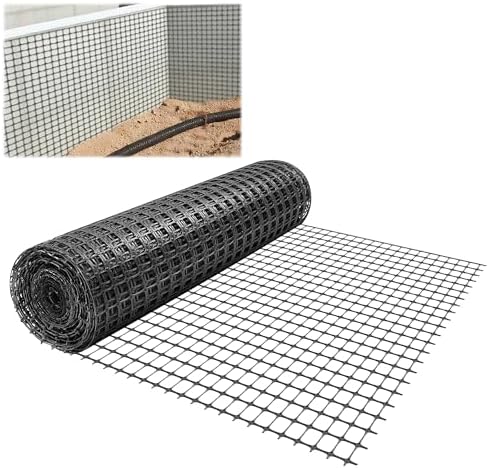

Geogrid reinforcement is an essential technology in the fields of construction and civil engineering, providing critical support in various applications such as soil stabilization, erosion control, and load distribution. Composed of a series of interconnected polymer or fiberglass fibers, geogrids serve to enhance the mechanical properties of soil by distributing loads over a larger area, thereby reducing settlement and improving overall site stability.

The primary function of geogrid reinforcement is to reinforce soils in embankments, retaining walls, and subgrade applications. When implemented appropriately, these materials can significantly enhance the durability and longevity of infrastructure. By effectively improving the load-bearing capacity of poor-quality soils, geogrids contribute to the design and construction of roadways, railways, and other critical structures. This, in turn, leads to better long-term performance and reduced maintenance costs.

Moreover, geogrids play a pivotal role in erosion control, particularly in areas prone to landslides or severe soil degradation. Their structural design allows for improved drainage and can be strategically incorporated into vegetative systems, promoting soil retention and the growth of sustainable vegetation over time. As a result, geogrid systems not only protect the integrity of slopes and embankments but also contribute to environmental stewardship by minimizing erosion rates.

The integration of geogrid reinforcement into construction practices exemplifies a proactive approach to engineering challenges. The continued advancement in manufacturing techniques and materials has enhanced the effectiveness of these reinforcements, making them an invaluable resource in modern construction projects. As such, it is essential to recognize the significant role played by manufacturers and suppliers in bringing high-quality geogrid solutions into the market, ensuring that construction professionals have access to the best tools for effective soil and structural reinforcement.

Major Geogrid Reinforcement Manufacturers

The geogrid reinforcement industry features several prominent manufacturers that play a critical role in providing innovative solutions for soil stabilization, road construction, and other civil engineering applications. Some of the leading players include Tensar International Corporation, NAUE GmbH & Co. KG, and Geogrid, Inc., each contributing distinct advantages that cater to various market needs.

Tensar International Corporation, founded in the 1980s, has established itself as a pioneer in the development of geosynthetic grid technology. Their product offerings include a wide range of geogrids designed for various applications, such as base reinforcement and slope stabilization. Tensar distinguishes itself through continuous technological innovation, focusing on enhancing product performance and sustainability methodologies that reduce environmental impact.

NAUE GmbH & Co. KG is another key manufacturer known for its commitment to high-quality standards and extensive product range. With a history spanning over 60 years, NAUE has developed geogrids that are engineered to provide exceptional durability and load-bearing capabilities. The company emphasizes sustainability practices, incorporating recycled materials into its products and promoting eco-friendly construction techniques. Their customer service model is characterized by a strong support system, ensuring client needs and project specifications are met with expertise.

Furthermore, Geogrid, Inc. maintains a significant presence in the geogrid market, specializing in providing customized solutions to meet unique project requirements. Their innovative manufacturing processes enable the production of high-performance geogrids that cater to critical infrastructure projects. Differentiation for Geogrid, Inc. lies in customer collaboration, where they actively engage with clients to tailor solutions that address specific geotechnical challenges. Through their advanced product offerings and technical support, they highlight the importance of reliability in the geogrid reinforcement industry.

Overall, the competitive landscape showcases manufacturers that are not only committed to quality and innovation but also prioritize sustainability and client satisfaction, making them key players in shaping the future of geogrid reinforcement technologies.

Top Geogrid Suppliers and Distributors

Geogrid suppliers and distributors play a crucial role in the supply chain of geogrid reinforcement products. These entities bridge the gap between manufacturers and end-users, ensuring that high-quality geogrids are readily available for various construction and engineering projects. A significant aspect of their operations is sourcing products from a wide range of manufacturers, which allows them to offer a comprehensive portfolio of geogrid types, each suited for different applications, such as soil stabilization, road construction, and retaining walls.

Many notable suppliers have established strong relationships with trusted geogrid manufacturers, enabling them to obtain products that meet stringent quality and performance standards. Through these partnerships, suppliers can quickly respond to market demands, thereby ensuring timely delivery of materials to their customers. Furthermore, suppliers often provide value-added services, such as technical support, installation guidance, and custom product solutions, which enhance the customer experience and foster long-lasting relationships.

Geographically, these suppliers operate on both local and international levels, giving them the flexibility to cater to various regions. Some of the leading distributors have devoted resources to developing logistics and supply chain strategies that facilitate efficient distribution. This capability is especially beneficial for fulfilling bulk orders and specific project requirements. Additionally, by adopting advanced technologies, suppliers are able to track and manage inventory effectively, ensuring that they can meet the diverse needs of clients, whether for large-scale construction projects or smaller municipal applications.

The competitive landscape of the geogrid supply market also drives innovation, compelling suppliers to develop solutions that meet evolving industry standards and compliance regulations. By prioritizing customer satisfaction and maintaining a robust inventory of geogrid reinforcement products, these suppliers are essential contributors to the successful execution of construction projects across various sectors and regions.

Future Trends in Geogrid Reinforcement Manufacturing and Supply

The geogrid reinforcement industry is poised for significant transformation driven by several key trends anticipated in the upcoming years. A primary focus will be on technological advancements that enhance the efficiency and effectiveness of manufacturing processes. Innovations such as automated production lines and advanced material science are expected to play a crucial role in enabling manufacturers to optimize production speed while ensuring product quality. The integration of smart technologies, such as IoT devices, within manufacturing plants will facilitate real-time monitoring and predictive maintenance, ultimately improving operational efficiency.

Additionally, sustainability practices are becoming increasingly important in the production of geogrid materials. Manufacturers are adopting eco-friendly raw materials and implementing circular economy principles aimed at reducing waste and energy consumption. This shift towards sustainable manufacturing aligns with evolving regulations that prioritize environmental responsibility. In response, companies are exploring biopolymers and recycled materials that can significantly reduce their carbon footprint while meeting market demands for sustainable solutions.

Market demand is also shifting, with an increasing emphasis on performance-driven solutions. Engineers and designers are seeking geogrid products that not only provide structural support but also enhance soil stability and longevity. This evolution is prompting manufacturers to invest in research and development to produce high-performance geogrids capable of withstanding diverse environmental conditions. Furthermore, as infrastructure projects grow in complexity, there is an observable trend toward customized geogrid solutions tailored to specific project requirements, positioning manufacturers who can offer flexibility as competitive leaders in the market.

Finally, the globalization of the geogrid supply chain is reshaping the way manufacturers and suppliers operate. With the rise of digital platforms, companies are not only reaching a broader customer base but also leveraging data analytics to better understand market trends and customer needs. As we move forward, it is clear that these trends will significantly influence the future landscape of geogrid reinforcement manufacturing and supply.

Contact information — Please use contact form on http://www.abshot.com/contact/